Steel has transformed how buildings are built in Canada. It’s strong, precise, and efficient to assemble. Whether it’s a two-storey home or a distribution centre, light-gauge steel frame construction makes projects faster, more sustainable, and more consistent.

Still, a lot of confusion surrounds how steel structures are planned and regulated. What exactly makes a steel frame safe? Which materials are acceptable under Canadian law? Why choose steel over other materials?

This post covers the essentials of basic steel structure design, framed by the National Building Code of Canada 2020 (NBC). It’s not a how-to manual—it’s a guide to the principles that matter, and the standards that ensure structural safety across different building types.

The Anatomy of a Steel Structure

A steel structure is an engineered system—made up of structural steel beams, columns, wall panels, and roof panels—that transfers loads safely to the ground. These structural components work together to resist everything from snow and wind to earthquakes and equipment weight.

In light-gauge construction, the materials are typically cold-formed steel. These are thin, precise components manufactured off-site and assembled quickly. Steel members like I beams, tie rods, and single angles are chosen based on how they carry stress and respond to force. Common steel shapes are selected to handle specific loads and span requirements efficiently.

You don’t see these parts once the building is finished—but they define how it performs for decades.

The Codes That Shape Design

Steel buildings in Canada are subject to the NBC. But for actual design, the code points to two key standards:

-

CSA S16 for structural steel (hot-rolled members)

-

CSA S136 for light-gauge, cold-formed steel

These set the rules for everything from yield strength and tensile strength to corrosion resistance and chemical composition. They also outline how to connect components—whether using welds, bolts, or self tapping screws. The foundation of structural steel design is ensuring every part of the steel construction aligns with both safety and performance criteria.

All this ensures steel components do more than fit together—they work together under real-world conditions.

Common Questions, Unpacked

Is there a “thumb rule” for steel structure design?

Not a single one. But there are typical starting points. For example, floor slab thickness often starts around 100 mm in light-duty applications. Beams may be spaced 1.2 to 1.5 metres apart. These are assumptions used in early planning. A proper design still requires detailed structural analysis.

What’s the standard method for structural design?

In Canada, most structural design follows Limit States Design (LSD). It evaluates what happens at two critical points: when a structure fails completely, and when it becomes too flexible or uncomfortable to use. This approach balances risk, cost, and performance—and it’s the legal standard.

What types of structural systems are used?

The system depends on the project. Rigid frames are common in open-plan commercial and industrial spaces. Braced frames handle lateral loads in areas with seismic risk. Continuous frames offer high strength and stability for taller or more complex structures. The best choice balances performance, cost, and construction efficiency.

What Makes Steel So Effective?

Steel is more than a substitute for wood or concrete. It opens up entirely new possibilities in design and construction. Because of its strength-to-weight ratio, it enables long spans and column-free interiors, ideal for warehouses, retail, and community spaces.

This flexibility is also evident in projects with specialized forms. For example, arch structures—common in sports facilities and terminals—rely on steel’s ductility and load-bearing precision. Steel’s ability to adapt across structural systems is one reason it's used everywhere from modular homes to airport terminals.

Key advantages include:

-

Steel can be prefabricated with incredible accuracy.

-

It performs well in high humidity and resists pests and rot.

-

Installation is fast, clean, and adaptable.

These benefits scale up or down, whether you’re building a detached home or a high-density complex.

Systems, Not Just Materials

The performance of any structural steelwork depends on how its parts interact. It’s not just about the steel beams—it’s about what they’re supporting, and how they connect.

Consider how a structure must handle loads in motion. Wind creates pressure differentials. Earthquakes introduce shifting lateral forces. Occupant movement and equipment produce dynamic stresses. It’s the system—columns, beams, ties, bracing, and connections—that maintains structural integrity.

Even the unseen details—like cover plates, steel decking, and properly engineered floor level joints—are critical. They ensure the building won’t just stand, but stay stable under repeated or shifting loads over time.

Where Light-Gauge Steel Shines

Light-gauge steel offers unique benefits in scenarios that demand flexibility, efficiency, and precision. It shines in:

-

Residential buildings that need consistent quality and speed

-

Commercial interiors where open floor systems reduce layout constraints

-

Remote builds, where fewer deliveries and minimal on-site cutting matter

In these contexts, steel's light weight reduces shipping demands and speeds up installation. Its pre-engineered precision also reduces jobsite errors—something that’s critical when you're trying to keep timelines tight and budgets intact.

At Innovative Living Design (ILD), we bring this efficiency to life through our tailored industrial steel frame construction systems.

Why ILD Is Different

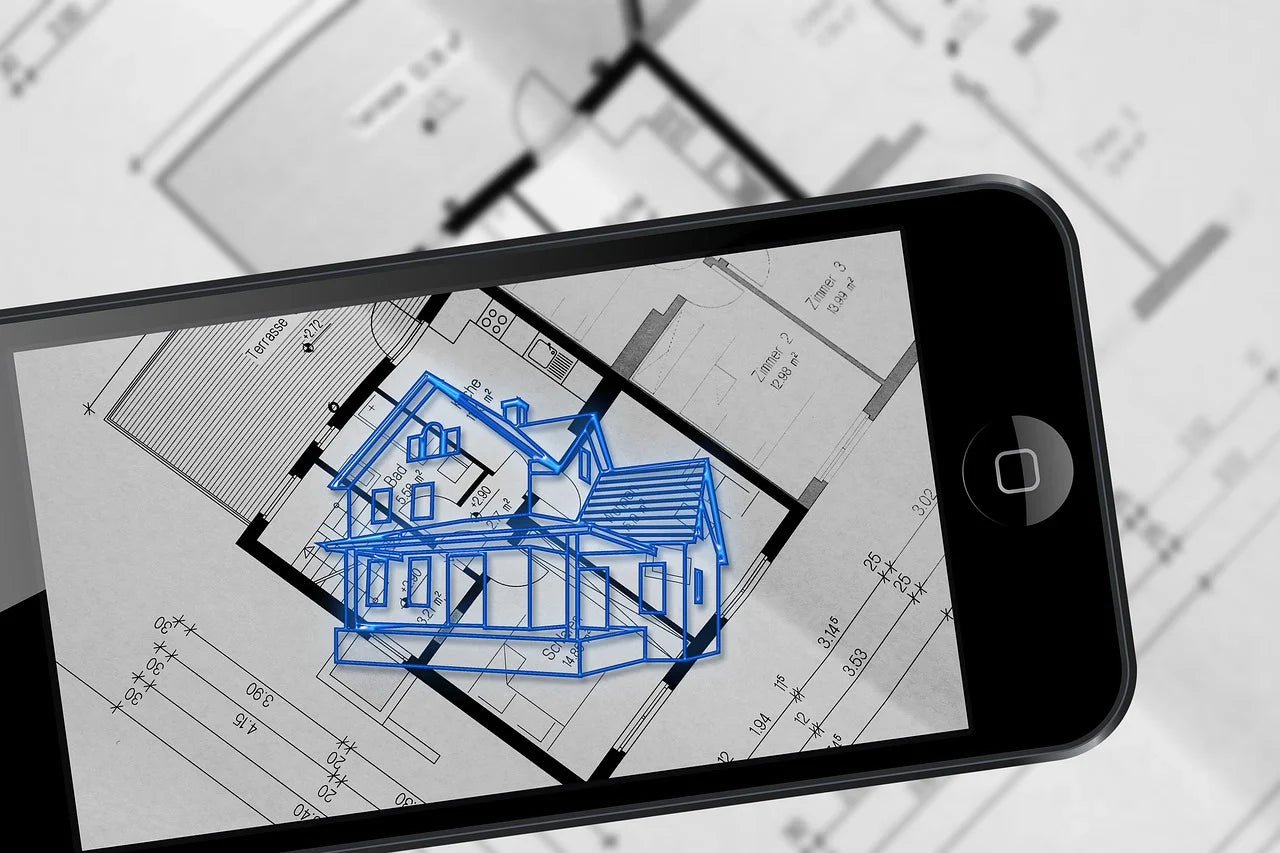

Our approach integrates precision design with efficient fabrication and on-site assembly, creating smarter structures that perform better over time.

What sets us apart is our control of the entire process. From digital modelling to fabrication of light-gauge components, we align every detail with climate, code, and client goals. The result: faster timelines, tighter coordination, and fewer compromises.

We specialize in adaptable, high-performance light-gauge steel solutions–Contact us to discuss your needs.