The construction industry isn’t short on disruption, but few shifts have the staying power of modular building. The global modular construction market was valued at USD 103.55 billion in 2024 and is expected to reach USD 162.42 billion by 2030. With a projected compound annual growth rate of 7.9% from 2025 onward, much of that momentum is tied to one urgent need: affordable housing. Clearly, modular construction is becoming a practical solution—not just a novel one.

That makes the question of modular vs traditional construction more relevant than ever. What exactly separates these methods? Which makes sense for your next project? And how do cost, speed, sustainability, and design flexibility really compare?

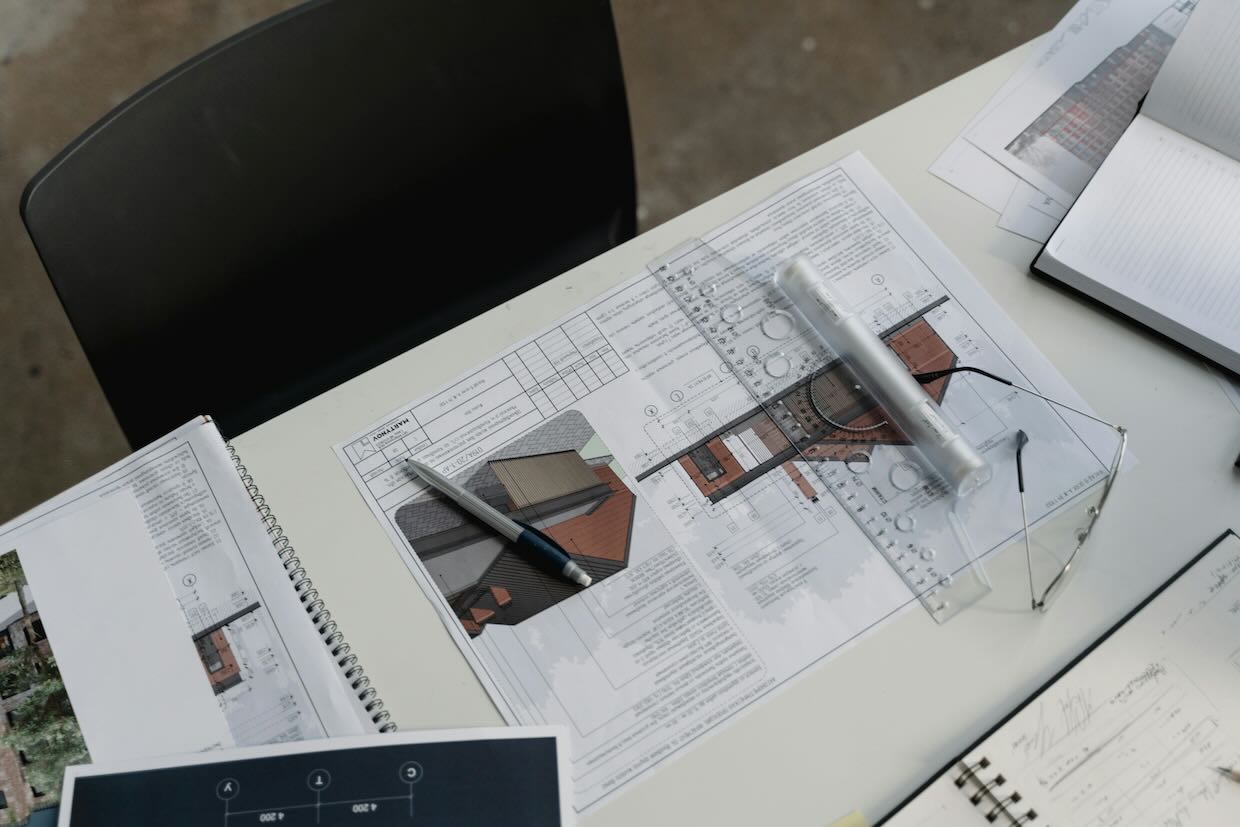

Comparing The Traditional & Modular Construction Process

Traditional construction is still considered by many to be the norm. It happens entirely on a construction site; building materials, skilled tradespeople, additional labour, and equipment come together on the property itself, and the project takes shape, piece by piece, over the course of weeks or months.

In modular, or prefabricated, construction, entire building components (modular units) are factory built. Those units are delivered to the project site and assembled on a prepared foundation. This approach works for everything from permanent modular buildings for residential or commercial needs to temporary modular buildings for limited, short-term needs.

Offsite vs Onsite Methods

Traditional building methods rely on a sequential flow—each phase can only start once the last finishes. Framing depends on site grading. Electrical can’t begin until the structure is enclosed. Every delay—whether from weather, trades availability, or permitting—ripples through the timeline.

Modular building construction compresses that process. While the foundation is being poured, the structure is being built off site. This overlap trims weeks, even months, off the schedule. And because the work is happening indoors, there are no weather delays, no lost days, and far tighter coordination across trades.

Construction Time

Modular construction consistently outperforms on schedule. Buildings go up in half the time of traditional builds, not because corners are cut, but because time is managed differently. Site work and structural work happen simultaneously. When the modules arrive, they’re installed in days, not months.

Modular vs Traditional Construction Costs

The cost of traditional construction depends on lots of factors; project creep, weather delays, and labour shortages can shift budgets significantly. When you take all the variables into account, it comes as no surprise that estimates are often pretty far from the actual cost in the end.

Modular construction projects are easier to keep on budget. The controlled factory setting eliminates guesswork, manages labor costs more efficiently, and significantly reduces material waste.

We’ve broken down what goes into the numbers in our light steel frame construction cost guide.

Quality Control: What’s Built Better?

It’s easy to assume that traditional buildings offer better craftsmanship. After all, you can see the work happening right there on site. But visibility doesn’t equal quality.

Modular construction offers something traditional methods can’t: precision manufacturing. In the factory, every element—from framing to finishing—is built under strict quality control measures. Trades work with consistent lighting, tools, and oversight. No rain. No snow. No cutting corners to “just get it closed in.”

Add in light steel framing—like we use at ILD—and you get a structure that won’t warp, rot, or burn. It’s stronger, straighter, and lasts longer than stick-built wood.

Flexibility and Design Freedom

The early days of modular construction, think boxy, cookie-cutter designs, are long gone. Modular building construction can support open layouts, large spans, custom finishes, and high-end facades. Even interior walls and complex MEP systems can be fully integrated.

Still, there are cases where traditional construction methods offer more flexibility, especially in heritage restoration or when integrating with unusually shaped existing structures. But for most commercial and residential builds, modular can meet or exceed design goals.

Sustainability and Environmental Impact

There’s no real contest here. Modular construction is cleaner, leaner, and lower impact.

Because everything is constructed off site, the carbon footprint tied to transportation, site waste, and air pollution is significantly reduced. Factory cutoffs get recycled. Deliveries are optimized. Fewer days on site means fewer emissions from generators, lifts, and trucks.

This matters. Not just for compliance, but for long-term performance. Modular builds align naturally with green building practices, energy efficiency, and low-waste construction.

Safer, Smarter Labour Conditions

It’s no secret that the construction industry is facing a skilled labor shortage. Traditional construction projects depend on coordinating multiple trades, often in tough conditions—extreme heat, snow, rain, or isolated sites.

Factory-based modular building changes that dynamic. Workers operate in climate-controlled environments with consistent workflows. It’s safer, more predictable, and more appealing to the next generation of skilled labor.

Code Compliance and Permitting

Permanent modular construction meets the same building codes as stick built construction. The difference is in execution, not regulation. From fire ratings to seismic loads to insulation values, there’s no shortcut.

How to Choose Between Modular & Traditional Construction

The answer depends on your priorities. But the pattern is clear:

Choose modular when:

-

Speed to occupancy is critical

-

Project sites are remote or constrained

-

Labor shortages drive up on-site costs

-

Quality control is a top priority

-

Sustainability and reduced waste matter

Use traditional when:

-

On-the-fly design changes are expected

-

The building must blend into a historic or irregular context

-

You’re doing major structural integration with older infrastructure

Final Word: Know the Tools, Use Them Well

This isn’t about modular vs traditional as opposing camps. It’s about understanding the options available—and choosing the right one for your goals.

Modular solutions with steel frame construction systems, offer a fast, reliable, and sustainable path forward for a huge range of construction projects. It’s not a shortcut. It’s a shift in how we think about building.

If you’re ready to rethink your next stick built project, we’re ready to help. Explore our residential and industrial steel frame solutions. If you want to learn more or are ready to get the ball rolling with a design request, call +1 (888) 666 7080 for specific inquiries or reach out online.